Blog

Orbital Welding in Pharmaceutical Application

In the dynamic world of pharmaceutical manufacturing, precision and purity are paramount. The convergence of advanced technologies and stringent industry standards brings forth a solution that has rapidly gained traction: Orbital Welding. Offering an impeccable fusion of metals, orbital welding emerges as an unsung hero, ensuring leak-proof, contaminant-free environments essential for orbital pharmaceutical processes. Dive into the intricacies of this cutting-edge technology as we explore its significance in orbital pharmaceutical applications.

Whether you're a seasoned professional, a budding engineer, or someone intrigued by the fusion of tech and health, understanding the role of orbital welding in this sphere promises insights into the future of drug production and purity assurance. Welcome to a world where every weld counts, and the marriage of technology and medicine shapes our tomorrow.

Orbital Welding in Pharmaceutical Applications: Precision and Purity

In the ever-evolving landscape of pharmaceutical manufacturing, precision and purity are paramount. The pharmaceutical industry demands the highest standards in quality control, and one technology that has risen to meet these rigorous requirements is orbital welding. This innovative welding technique has revolutionized the way critical components are joined in orbital pharmaceutical applications, offering a range of benefits that ensure product integrity, compliance, and efficiency.

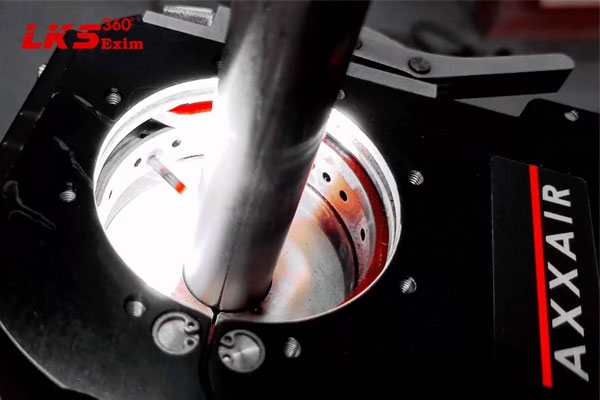

Orbital welding is a highly specialized method that employs an automated welding head to rotate around the workpiece, creating a consistent and uniform weld. This precision is crucial in pharmaceutical applications, where even the slightest contamination or inconsistency can compromise the safety and efficacy of pharmaceutical products. Unlike traditional welding methods, orbital welding eliminates the risk of human error, resulting in flawless, repeatable welds.

One of the primary advantages of orbital welding in pharmaceutical ( orbital pharmaceutical) applications is its ability to maintain the integrity of ultra-pure systems. In pharmaceutical manufacturing, systems must be free from contaminants to ensure the highest quality of products. Orbital welding, with its gas-tight seals and minimal heat-affected zones, reduces the likelihood of particulate contamination and ensures the sterility of the final product.

Moreover, orbital welding contributes to enhanced efficiency and productivity. Its automated nature reduces downtime and labor costs, while the precise control over parameters such as heat input and travel speed ensures consistent weld quality. This efficiency translates into shorter production times and ultimately a more competitive pharmaceutical manufacturing process.

Furthermore, compliance with regulatory standards is a top priority in the orbital pharmaceutical industry. Orbital welding facilitates compliance by providing documentation and traceability of weld parameters, making it easier for manufacturers to demonstrate adherence to stringent quality and safety regulations. This not only safeguards public health but also helps pharmaceutical companies avoid costly fines and reputation-damaging recalls.

Orbital welding has become an indispensable tool in pharmaceutical manufacturing, offering precision, purity, efficiency, and compliance. Its ability to produce consistent, high-quality welds in ultra-pure systems is crucial for ensuring the safety and efficacy of pharmaceutical products. As the pharmaceutical industry continues to advance, orbital welding stands as a shining example of how technology can elevate quality and reliability to unprecedented levels, ultimately benefiting both manufacturers and consumers alike.

=> Read more at :

=>Orbital Pharmaceutical Welding: The Pivotal Role of Orbital Welding Machines

=>Why Orbital Welding Technology is Popular in the Pharmaceutical Sector

LKS provides orbital pharmaceutical Solutions

LKS is at the forefront of cutting-edge technology, offering state-of-the-art orbital welding machines tailored specifically for the pharmaceutical industry. With a focus on precision and quality, LKS's welding solutions are meticulously designed to meet the stringent standards and exacting demands of orbital pharmaceuticals. These machines not only ensure impeccable welds but also guarantee the integrity and sterility of critical components within pharmaceutical equipment. As a result, LKS provides orbital pharmaceutical solutions for pharmaceutical companies to maintain the highest levels of product quality, compliance, and efficiency, ultimately contributing to the safety and well-being of patients worldwide. Embracing innovation and precision, LKS 360 EXIM stands as a trusted partner in the pharmaceutical industry's quest for excellence in production and reliability, providing solutions that are as exceptional as they are indispensable.

LKS 360 EXIM stands as a beacon of innovation and excellence in the field of orbital welding machines, orbital pharmaceuticals and offering tailored solutions designed to elevate the pharmaceutical industry's manufacturing processes to new heights. With an unwavering commitment to precision and quality, LKS ensures that pharmaceutical companies can maintain the highest standards of product integrity, compliance, and efficiency.

By partnering with LKS 360 EXIM , these companies not only secure their reputation for delivering safe and reliable medications but also contribute to the well-being of patients around the world. In an industry where precision and sterility are paramount, LKS's orbital welding machines emerge as the indispensable choice, symbolizing a dedication to excellence that resonates throughout the pharmaceutical sector. As the pharmaceutical landscape continues to evolve, LKS remains at the forefront, delivering solutions that are as unique as they are essential, setting a new standard for orbital welding technology in the pharmaceutical industry (orbital pharmaceutical).

LKS 360 Import Export Trading Service Co., Ltd

Hotline: 02866.503.603

Website: lks360exim.com

Blog