Blog

Orbital welding standards in the pharmaceutical industry (Orbital pharmaceutical)

In the meticulously regulated world of pharmaceutical manufacturing, every detail counts — especially when it comes to the integrity of the infrastructure that carries the lifeblood of medicine: its piping systems. Orbital welding technology stands at the forefront of this industry, not just as a process but as a benchmark for excellence and safety. Orbital Pharmaceutical, where automated equipment performs circular welds around pipes, is not merely about joining metals; it’s about upholding the most stringent standards to ensure product purity, safety, and efficacy.

The adherence to robust orbital welding standards is non-negotiable in the pharmaceutical landscape. These standards are not just guidelines but are the pillars supporting the entire fabrication process of pharmaceutical components, ensuring leak-proof, contaminant-free systems that can withstand the rigorous demands of medicine production.

This article delves deep into the world of orbital welding standards within the pharmaceutical sector, known colloquially as Orbital Pharmaceutical. LKS 360 Exim will explore the precision of the process, the regulations that govern it, and the unwavering commitment to quality that it symbolizes. From the highly specialized materials used in the welds to the advanced technology driving the welding equipment, we'll dissect every aspect that makes orbital welding a cornerstone of pharmaceutical manufacturing.

Standards and Regulations

Orbital welding in the pharmaceutical industry is not just about precision and efficiency; it's a dance with standards and regulations where every step is choreographed to perfection. In this realm, specific orbital welding standards reign supreme, ensuring that installations are not only robust but also in stringent alignment with the health sector's expectations. The regulators, like the FDA and those enforcing Good Manufacturing Practices (GMP), are the invisible audience, scrutinizing each weld for compliance.

At the heart of this meticulous process is the ASME Bioprocessing Equipment (BPE) standard, which serves as the standards for weld quality and consistency. The Orbital Pharmaceutical standard is not just a guideline but the foundation upon which pharmaceutical welding operations construct their legacy of purity and reliability.

Material and Equipment Considerations

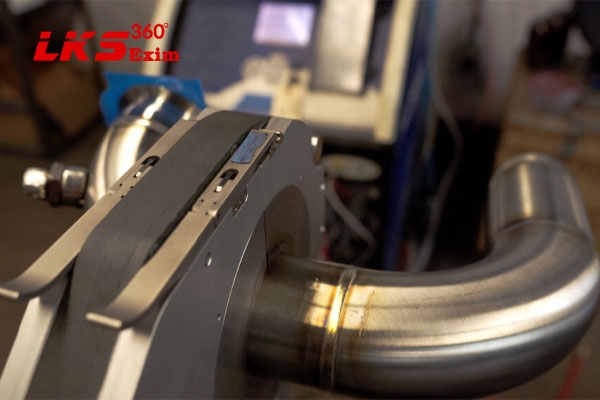

The materials and equipment used are the stars of Orbital Pharmaceutical welding. From the corrosion-resistant stainless steel to the cutting-edge orbital welding technology, each element is chosen with a singular focus on quality. The selection criteria for welding equipment are not just about performance but also about adaptability to the rigors of pharma-grade compliance.

Quality and Compliance

Quality control is the guardian of integrity in Orbital Pharmaceutical, with measures that leave no stone unturned in ensuring the sanctity of the welds. Cleanliness and contamination prevention are not just buzzwords; they're the principles that guide the entire operation. And when it comes to documentation and validation, the industry embraces a meticulous approach, creating a paper trail as pristine as the piping systems it accompanies.

Enhanced Efficiency and Cost-effectiveness

Beyond its precision and compliance benefits, orbital welding introduces a new era of efficiency to pharmaceutical manufacturing. The automated nature of the process reduces production time and, consequently, operational costs. Orbital Pharmaceutical welding not only streamlines the manufacturing workflow but also contributes to the overall competitiveness of pharmaceutical companies in the market.

=> See more articles on the same topic at:

=> Tips To Avoid a Lack of Fusion in Orbital Welding in pharmaceutical (Orbital pharmaceutical)

=> Orbital Welding For Pharmaceutical Tubing (Orbital Pharmaceutical)

Versatility in Application

Orbital welding's versatility extends beyond its application in the primary pharmaceutical manufacturing process. From the construction of cleanrooms to the assembly of piping systems, its adaptability makes it a valuable asset throughout the entire pharmaceutical production lifecycle. This versatility positions orbital welding as a holistic solution that addresses various facets of pharmaceutical manufacturing.

Challenges and Solutions

Yet, Orbital Pharmaceutical welding is not without its challenges. From the unforgiving precision required in welds to the evolving standards, the industry faces hurdles that demand innovation and adaptability. The best practices that emerge are a testament to the industry's commitment to excellence, showcasing a relentless pursuit of solutions that not only solve but also advance the art of orbital welding in the pharmaceutical landscape.

In forging this path, the industry sets a benchmark not just in welding, but in the holistic approach to health-centric manufacturing, where every weld, every joint, and every pipe is a tribute to the uncompromising quest for perfection.

As the pharmaceutical industry continues to evolve, embracing cutting-edge technologies is essential to staying ahead of the curve. Orbital welding standards represent a paradigm shift in precision, compliance, and efficiency within pharmaceutical manufacturing. With the potential to revolutionize the way medications are produced, Orbital Pharmaceutical Welding is not merely an option but a necessity for companies aiming to deliver the highest quality pharmaceuticals to the global market. By integrating orbital welding into their processes, pharmaceutical manufacturers can elevate their standards, ensuring that every medication produced is a testament to innovation, quality, and safety.

LKS 360 Import Export Trading Service Co., Ltd

Hotline: 02866.503.603

Website: lks360exim.com

Blog